Processing of T-, L- and U-steel girders

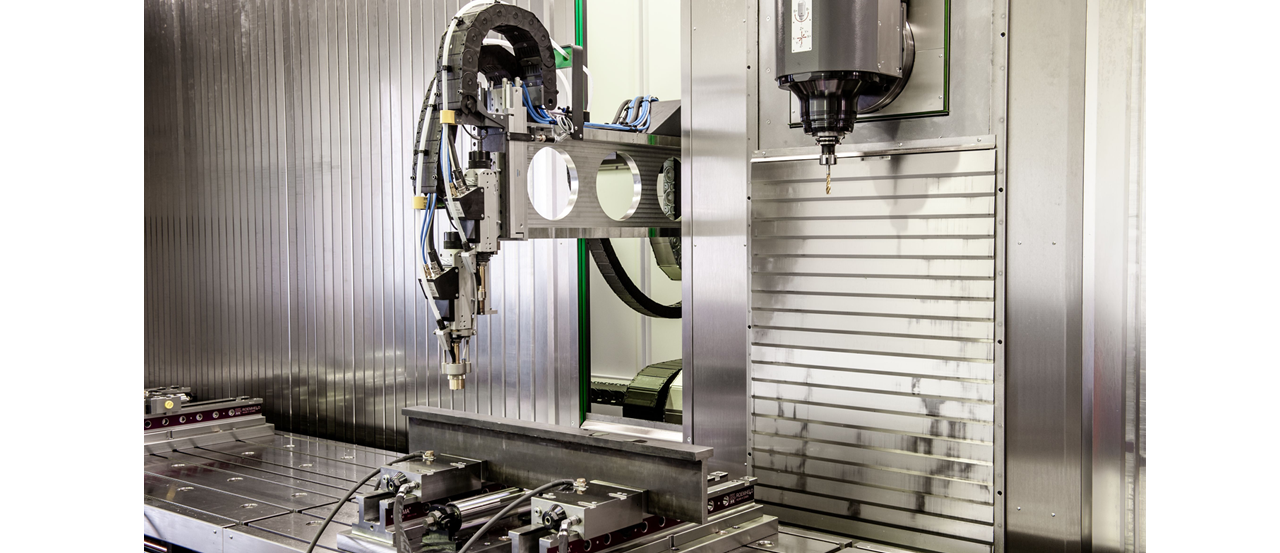

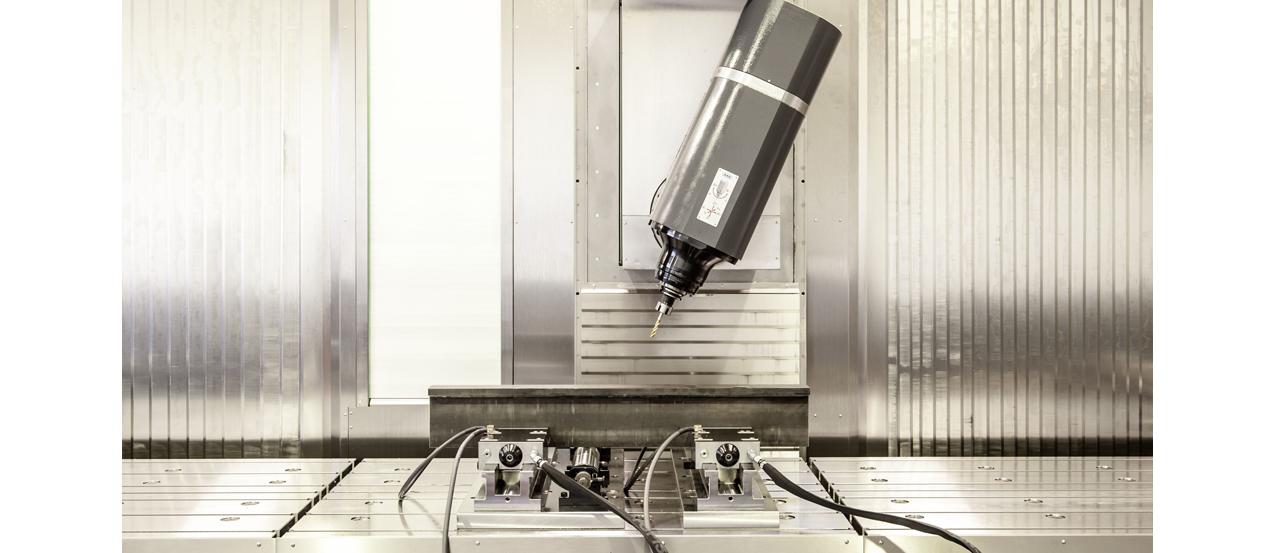

Machine type: VHC 3 XTS

Application:Processing of T-, L- and U-steel girders for glass fronts | |

Task:Milling processing and spot welding of threaded bolts in one single clamping process | |

Solution:The mechanical process takes place on the VHC 3 (standard series). Two welding heads have been integrated to weld the threaded bolts that are positioned next to the travelling column. One welding head is for M6 and the second for M8 threaded bolts. These welding heads move in the X-axis with the travelling column and have their own independent Y and Y axes as well, thus enabling welding in the entire working area. The threaded bolts automatically are inserted by a vibrating hopper that moves alongside it. | |

Special feature:

|