Task:Milling of rolled steel profiles up to 8.8 m in length (lift masts for forklifts and high rack warehouses) |

Solution:- Standard travelling column machining centre with horizontal SK 60 spindle

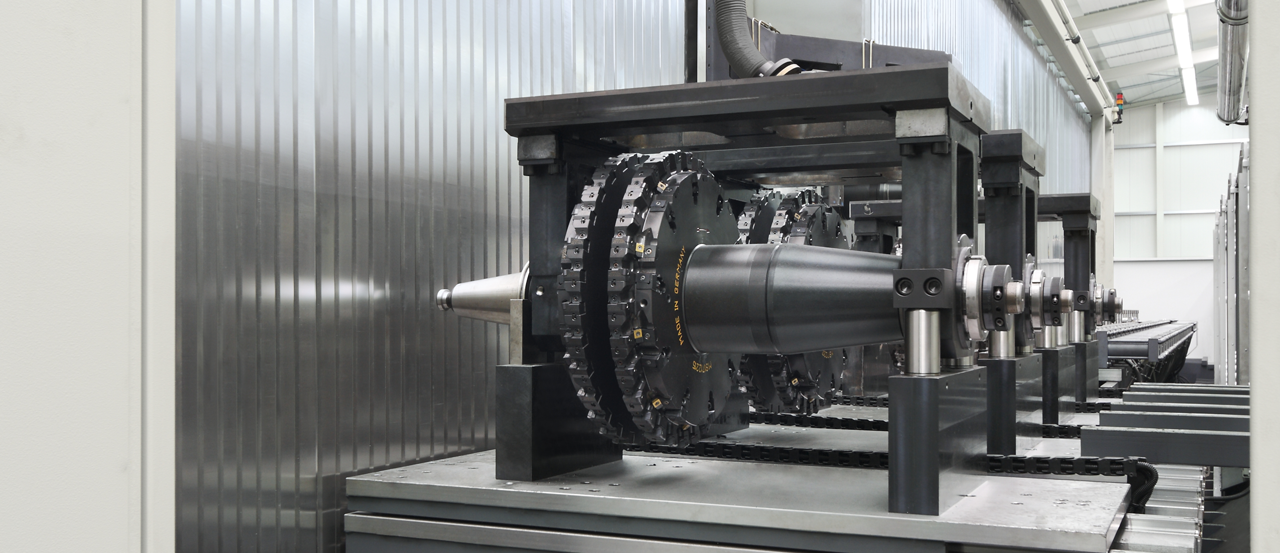

- Four tools in a pick-up magazine, consisting of an SK 60 milling cutter with counter bearing, each fitted with

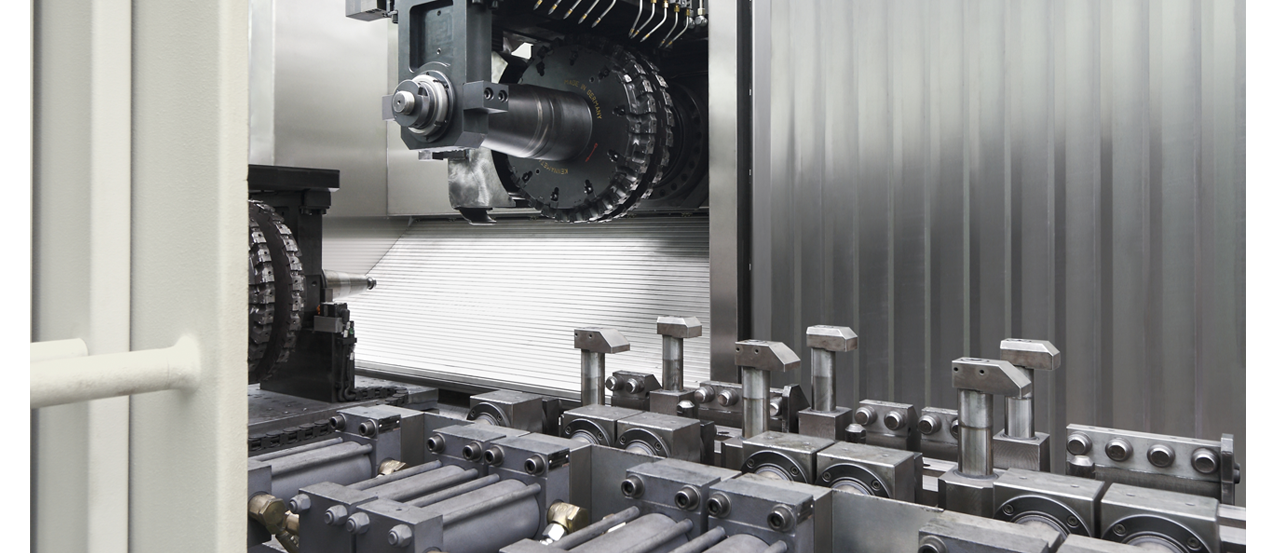

4 disc cutters of D = 500 mm - Hydraulic workpiece clamping device

|

Special characteristics:- Prepared for unmanned operation with automated loading and unloading

- Identification of the raw workpieces lying on the conveyor belt by means of a camera system

- Prefabricated parts are inserted into the clamping device and removed by means of a gantry loader

- Automated clamping device for optimal workpiece clamping

- High-performance chip extractor running in parallel on the X axis

|

Traverse ranges:X-traverse range: 12000 mm

Y-traverse range: 600 mm

Z-traverse range: 525 mm |

Spindle:Main spindle drive (with 100% DC): 66 kW

Torque (with 40% DC): 3200 Nm

Speed range: 10 - 500 1/min |

Tool changing system:4 tool places SK 60 |