Machining special shafts and pipes

Maschinentyp: VHC

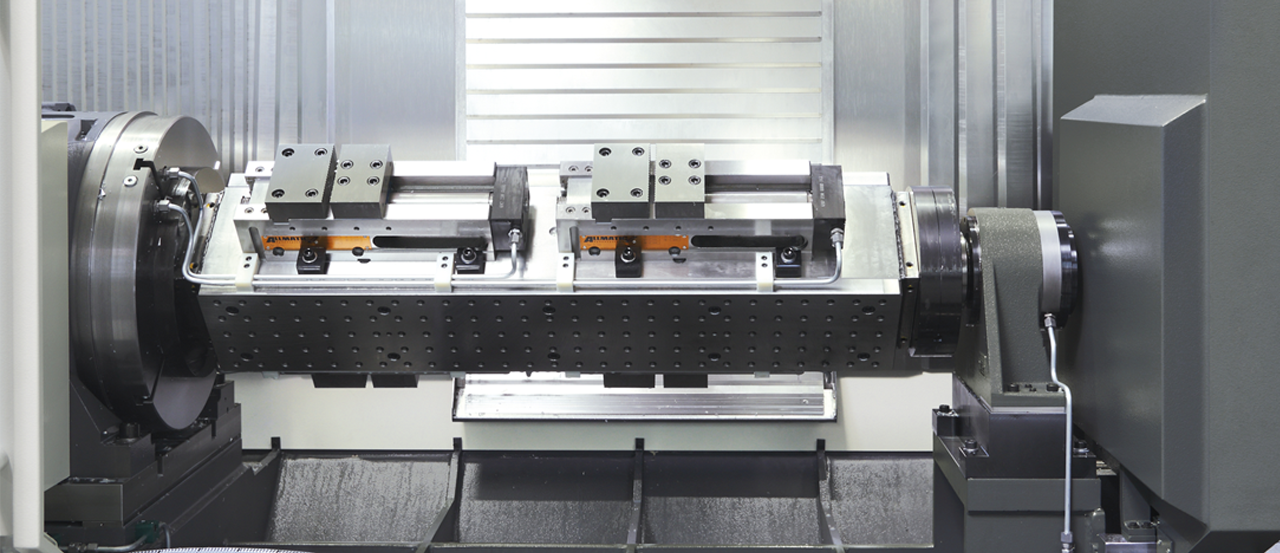

tailstock installed on the right-hand side

Task:Machining special shafts and pipes |

Solution:

|

|

Traverse ranges:X-traverse range: 3000 (2 x 1250) mm |

Spindle:Main spindle drive (with 40% DC): 56 kW |

Tool changing system:XTS tool magazine, 2 x tool towers with 120 places + pick up station |

Rotary table:2 x NC rotary table RTA 4L-520 |

Swivel head:Infinitely variable +/- 90° |