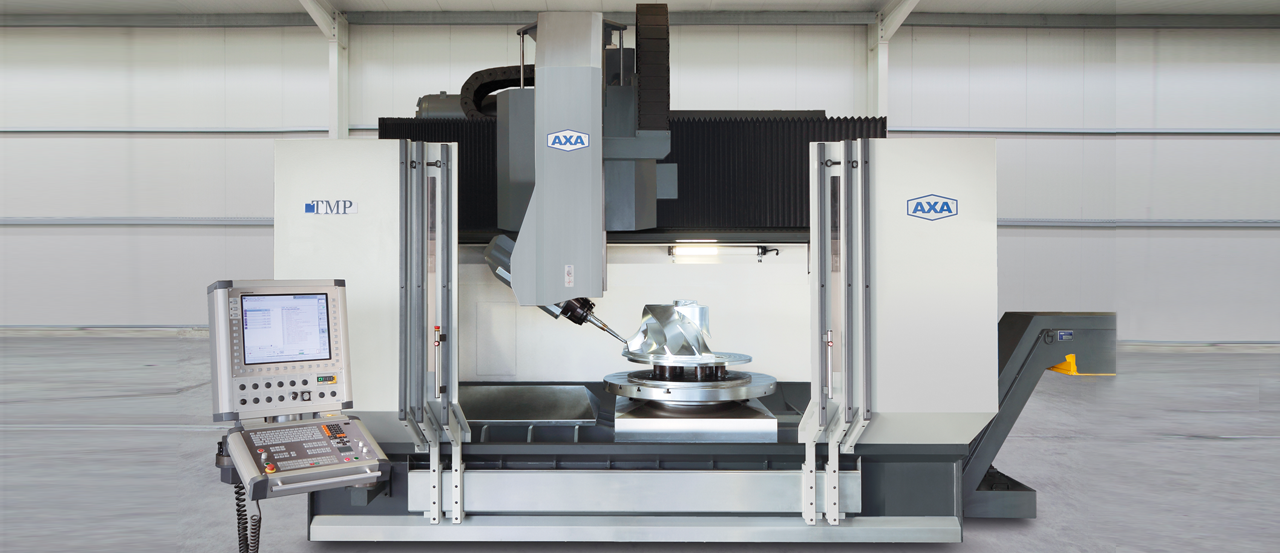

TMP - Gantry machining centre

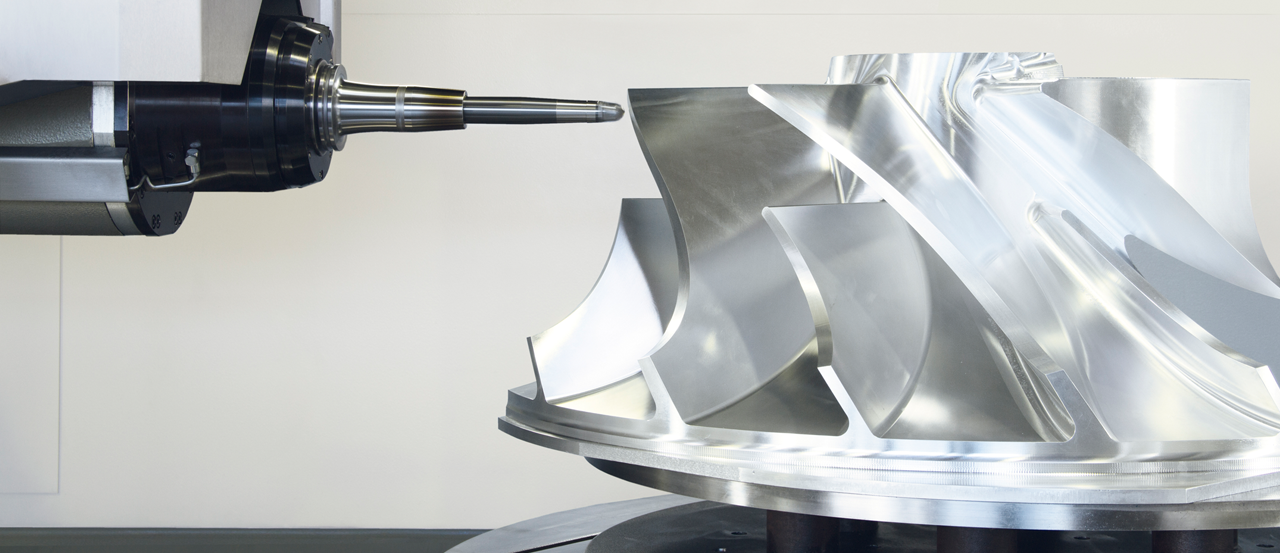

This 5-axis portal machining centre stems from our compact series and has been designed for users in the realms of high-end mould making for large-scale workpieces. The main application focus for the TMP is processing turbines, impellers, gear wheels and Pelton runners.

Large-scale, bulky workpieces can also be processed with utmost precision on the TMP. The combination of powerful swivelling spindle and a fast turning NC rotary table with a clamping surface of up to 1600 mm enables the 5-axis simultaneous processing of large-scale workpieces with a load of up to 5 t and a swivel range of up to 2100 mm.

Traverse ranges:

X = 2300 mm - 2940 mm (vertical)

X = 2000 mm - 2640 mm (horizontal)

Y = 1400 mm - 1800 mm

Z = 900 mm

Main design

Main design

- Extremely rigid, static and dynamically well-balanced ground frame construction

- Spacious and easily accessible machine table

- Direct measuring systems for the X/Y/Z-axes and swivelling axes B/C

- Through spindle and external cooling optionally with air and emulsion

- Machine transport in one single piece

- Optimal accessibility for all maintenance and service requirements

We are able to develop and manufacture special solutions for you upon request.

Guideways and drives

Guideways and drives

- Solid roller guides, generously dimensioned for high dynamics, stiffness and accuracy

- Guiding built upon manually scraped or grinded surface

- Real gantry drive in the Y-axis with corresponding individual drive, guideway and direct measuring system for both portal sides

- Drives and guideways are protected

- Fully temperature-controlled machine including water-cooled and high performance ball screw in X/Y

Tool changing system

Tool changing system

- Tool shop with double gripping system

- Magazine protected in rear part of machine

- 20 to 90 tool places

- Fixed location coded tool management for better operator monitoring

- Simultaneous tool pre-selection

- Support of various tool holding systems

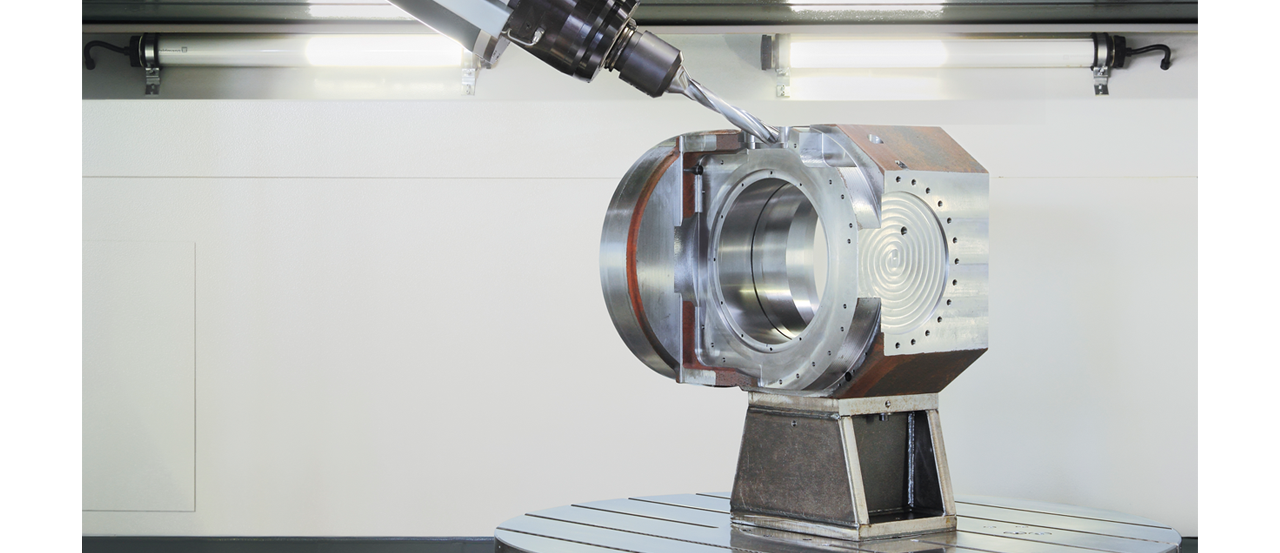

Tilting spindle

Tilting spindle

- Powerful SK 50 tilting spindle, max. 9000 rpm

- Ooptional HSK A63, max. 18.000 rmp

- 1-axis tilting spindle swivelling around the Y-axis (B-axis)

- Stepless, interpolating construction

- Tilting range 0° to -100°

Technical data

Technical data

Click to open or download the technical data as pdf file.

Product brochure

Product brochure

For more information about our TMP please have a look at the brochure. Click here to open or download the brochure as pdf file.