Task:Machining base frames for knitting machines |

Solution:- Around 20 racks are stored in a high rack axially in front of the machine

- The workpiece is inserted into the hydraulic clamping device by means of a gantry loader

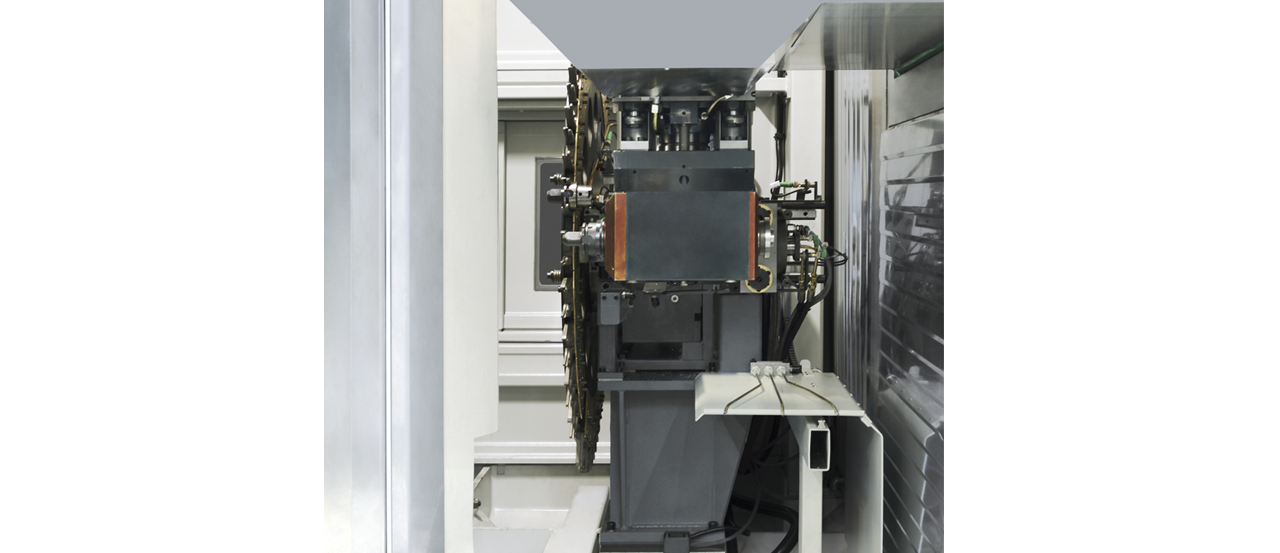

- Complete machining by means of 2 swivel heads with HSK A100 spindles

|

Special characteristics:- 2 angular milling heads above a stable four-point support on the spindle with integral HSK A63 tool clamp

- Each angular milling head has its own 32-fold tool plate

|

Traverse ranges of each travelling column:X-traverse range: 6200 mm

Y-traverse range: 900 mm

Z-traverse range: 800 mm |

Spindle:Main spindle drive (with 40% DC): each 45 kW

Torque (with 40% DC): each 286 Nm

Speed range: each 7500 1/min |

Tool changing system:XTS tool magazines with each 46 tool places (HSK A100)

Plate-tool-shops with each 32 tool places (HSK A63) |

Swivel head:individual sviwel heads (A-axes) |