5-axis machining in a compact footprint

Our new machine series:

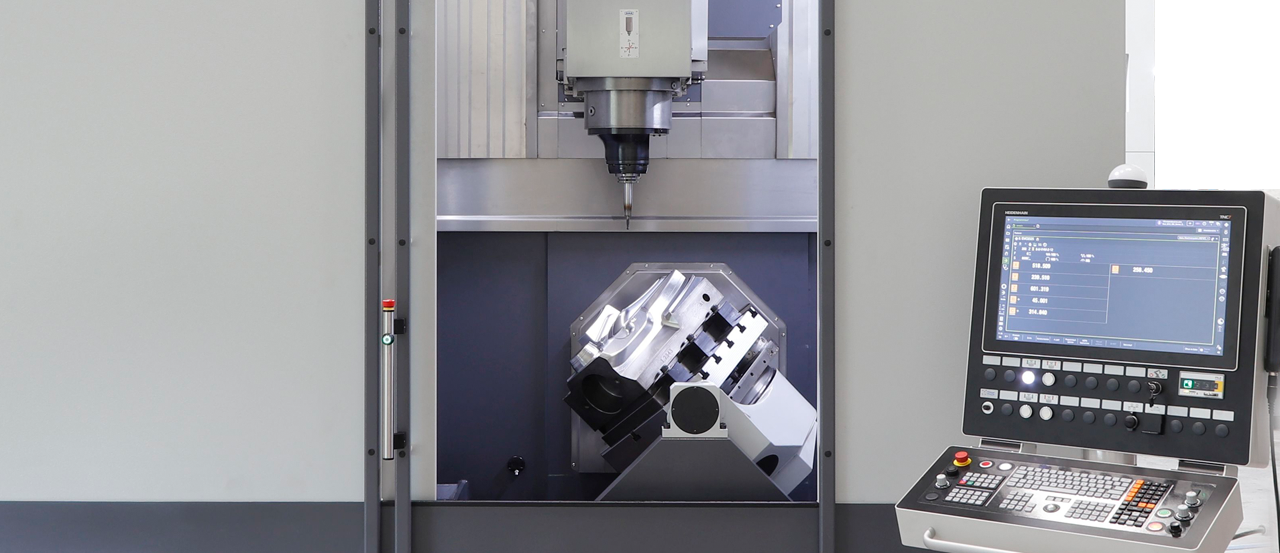

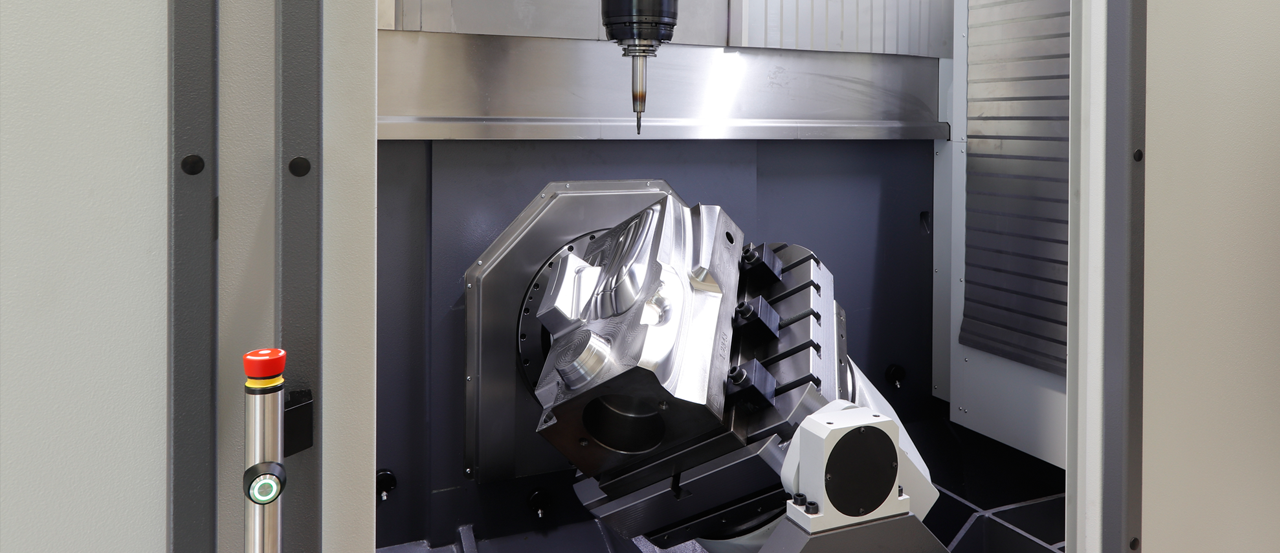

The VSR 2 travelling-column machining centre is fitted as standard with a tilting rotary table that pivots around the Y-axis. Unlike conventional X-axis solutions, this innovation gives the operator an unobstructed view of any potential interfering contours during machining.

With its compact footprint, the machine is perfectly suited for 5-axis and 5-sided machining of smaller components.

Traverse ranges:

X = 1100 mm

Y = 600 mm

Z = 700 mm

2-axix tilting rotary table

2-axix tilting rotary table

2-axis tilting rotary table tilting around the Y-axis:

- Unlike the usual tilting around the X-axis, this solution allows a clear view of any interfering contours.

- Face plate 550 x 550 mm with rounded corners, r=325 mm

- Optional additional face plates with zero-point clamps or T-slots

- Swivel range +/- 110°

- Direct drive and direct measuring system for B-axis (Swivel axis) and C-axis (rotary table axis)

- Feed drive swivel axis max. 60 rpm

- Feed drive rotary table axis max. 100 rpm

Extremely compact

Extremely compact

- The VSR requires an unusually small footprint of around 12 square metres.

- The rear is completely closed so that the machine can be placed directly against a wall.

Space-saving tool magazine

Space-saving tool magazine

- Stationary placed chain magazine outside of working area

- XTS-magazine tower with up to three chains for 60 tools each

- Max. 180 tool places in total with a length of up to 400 mm

High Z-axis travel

High Z-axis travel

With 700 mm higher than usual - for maximum flexibility with a wide variety of component geometries

Robot interface

Robot interface

- The travelling column design allows for a side lifting gate for automated loading.

- This connection does not obstruct access to the work area and allows for unrestricted operation.

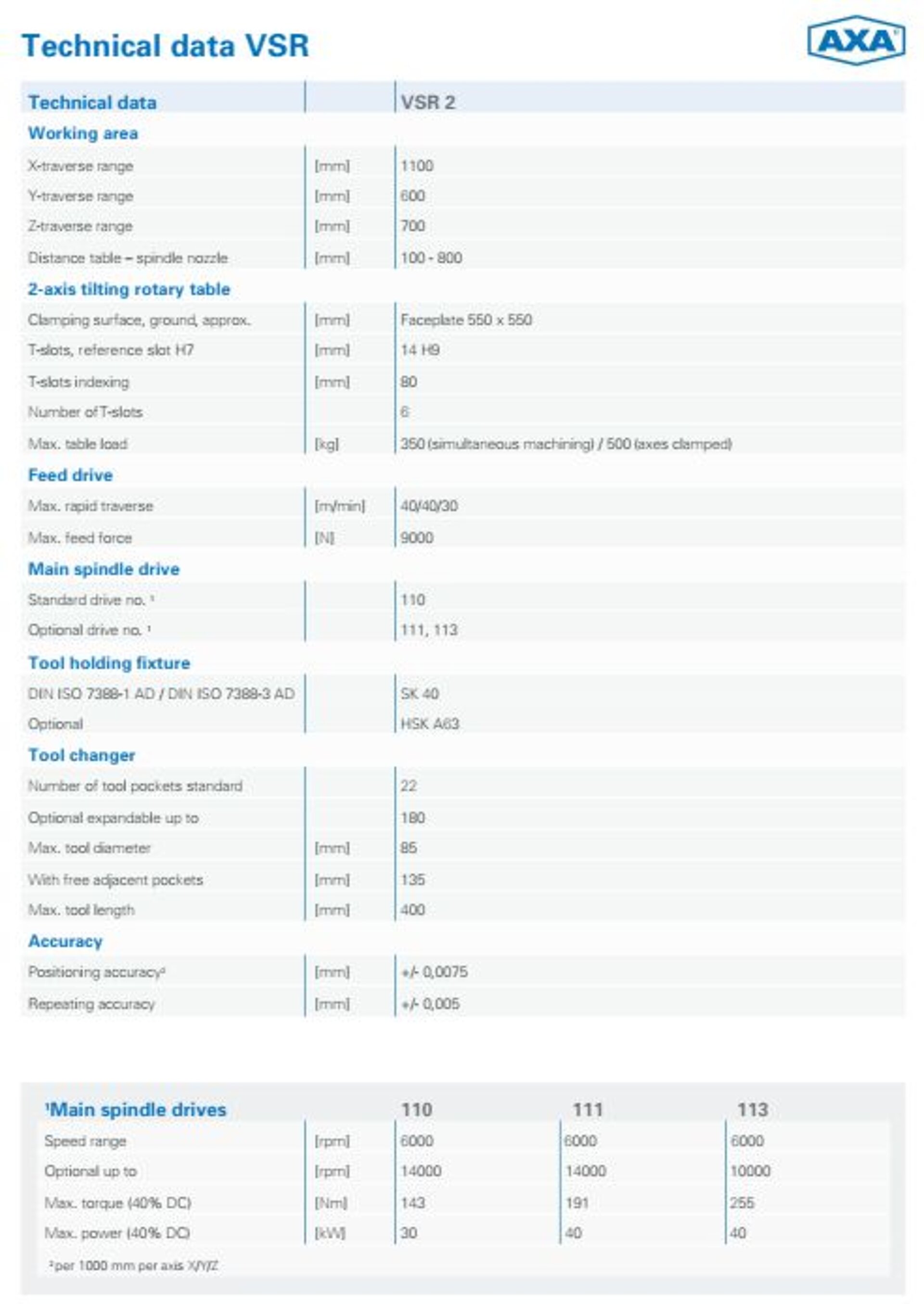

Technical data

Product brochure

Product brochure

For more information about our VSR please have a look at the product brochure. Click here to open or download the pdf file.

Video

Video