Clamping technology

the retooling times

Clamping technology

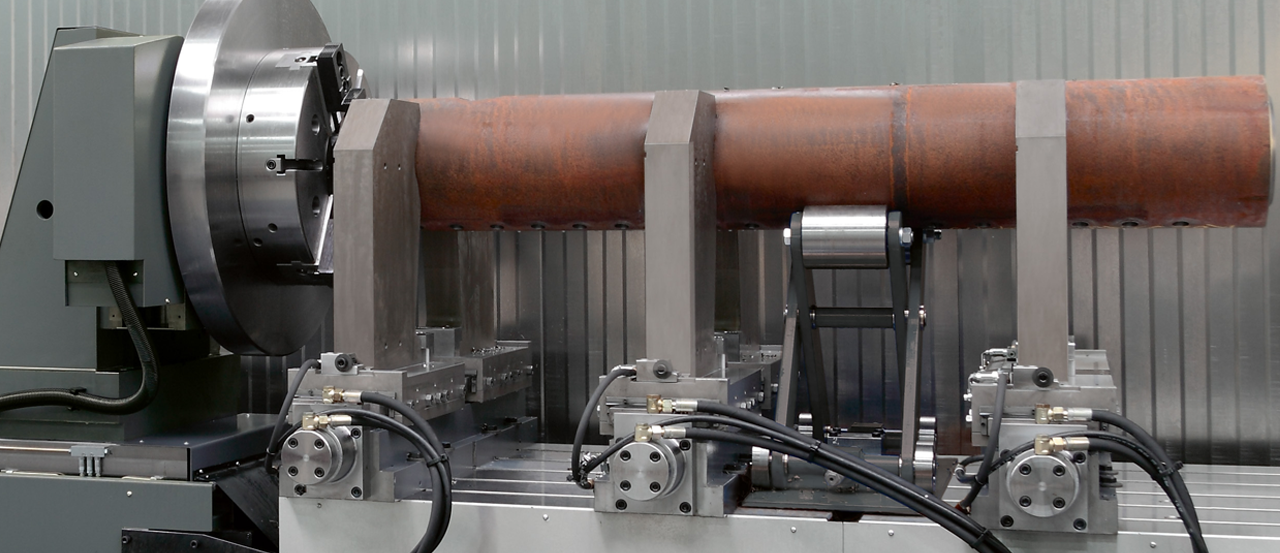

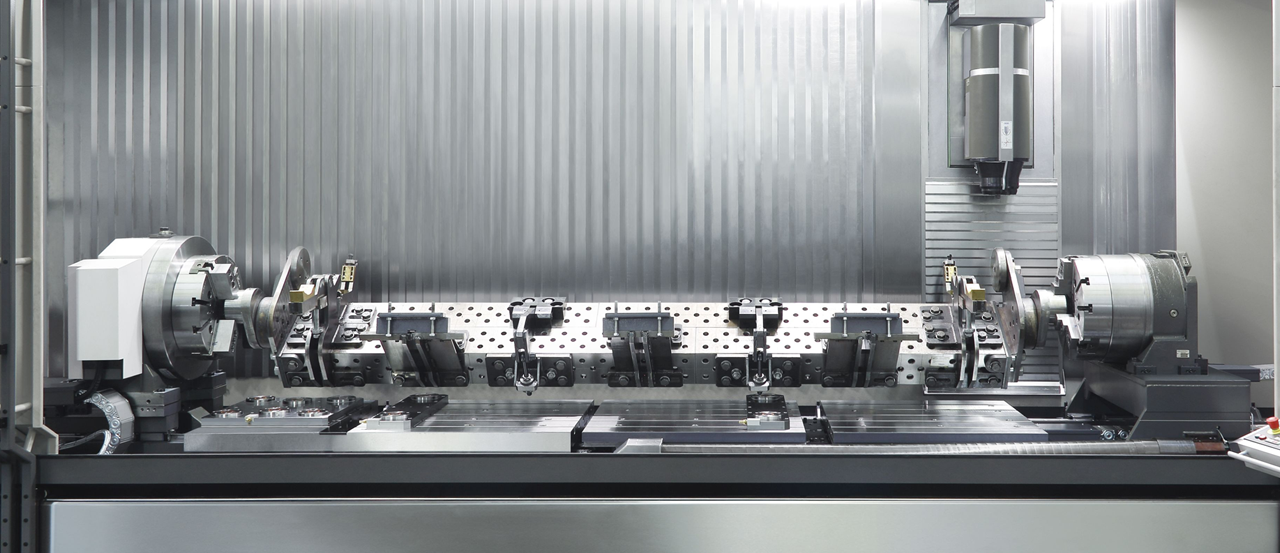

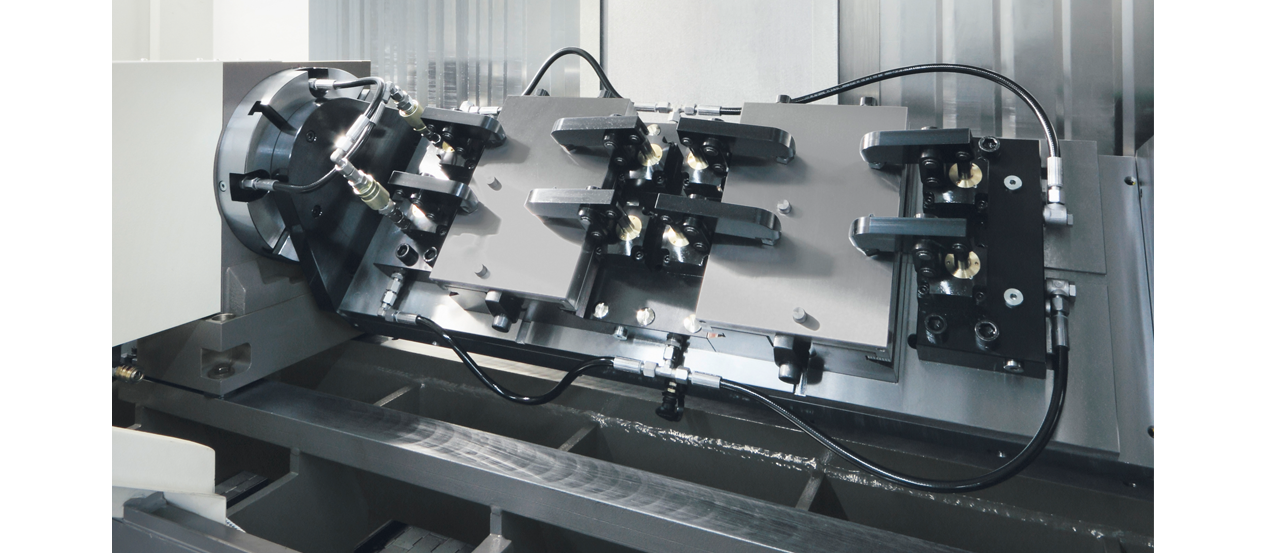

Workpieces must be fixed and held in position in order to be able to process them safely, quickly and efficiently. Depending on the shape, size and material of the workpiece, different clamping technologies and clamping devices are used. Regardless whether mechanical, hydraulic, magnetic or vacuum technology - we at AXA Maschinenbau develop individual solutions or integrate existing systems. Together with numerous partners, we find the correct clamping technology.

AXA clamping solutions

AXA clamping solutions

- Chucks or clamping devices

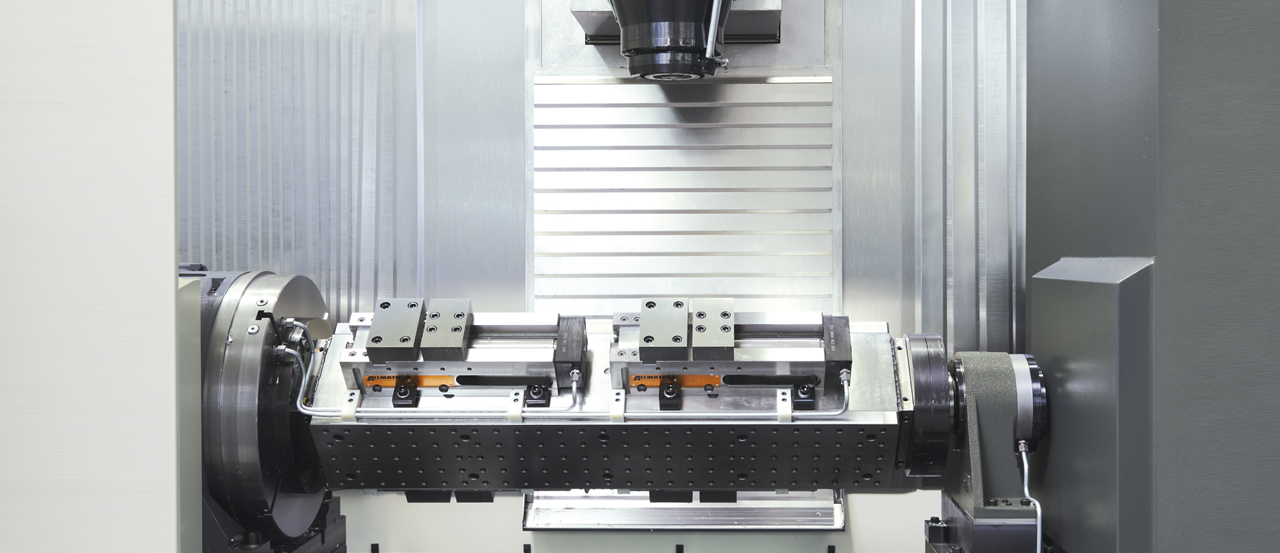

- Machine vices

- Centering vices

- Box jaws

- Multiple clamping systems

- Clamping towers

- Simple table clamping systems

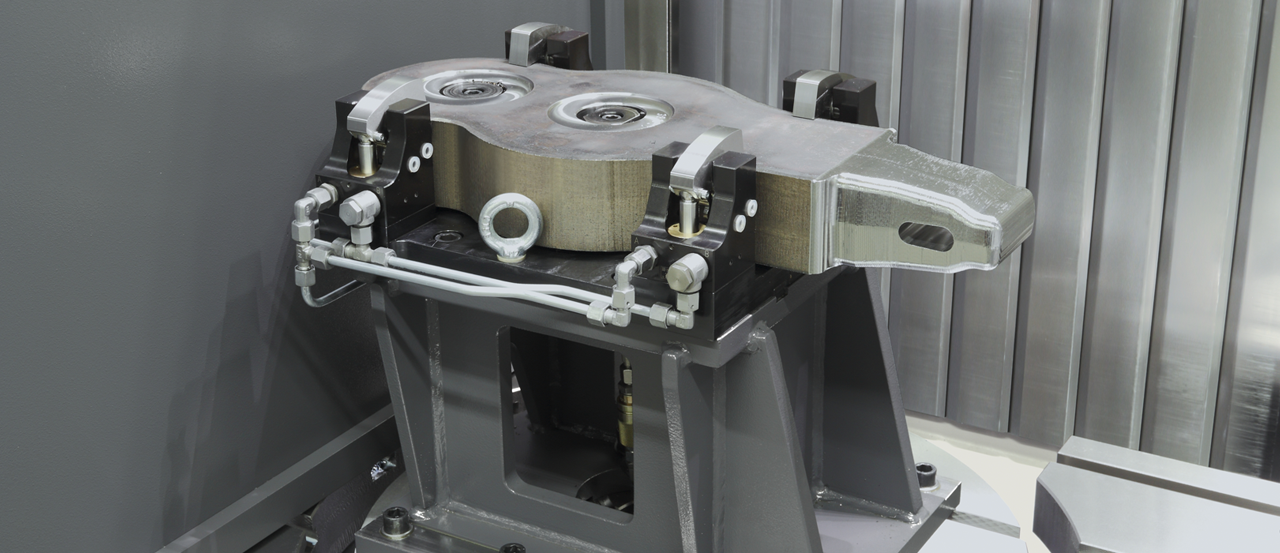

- Clamps of moulded parts with special clamping system