Machining of battery housing parts for high-voltage batteries in electric cars

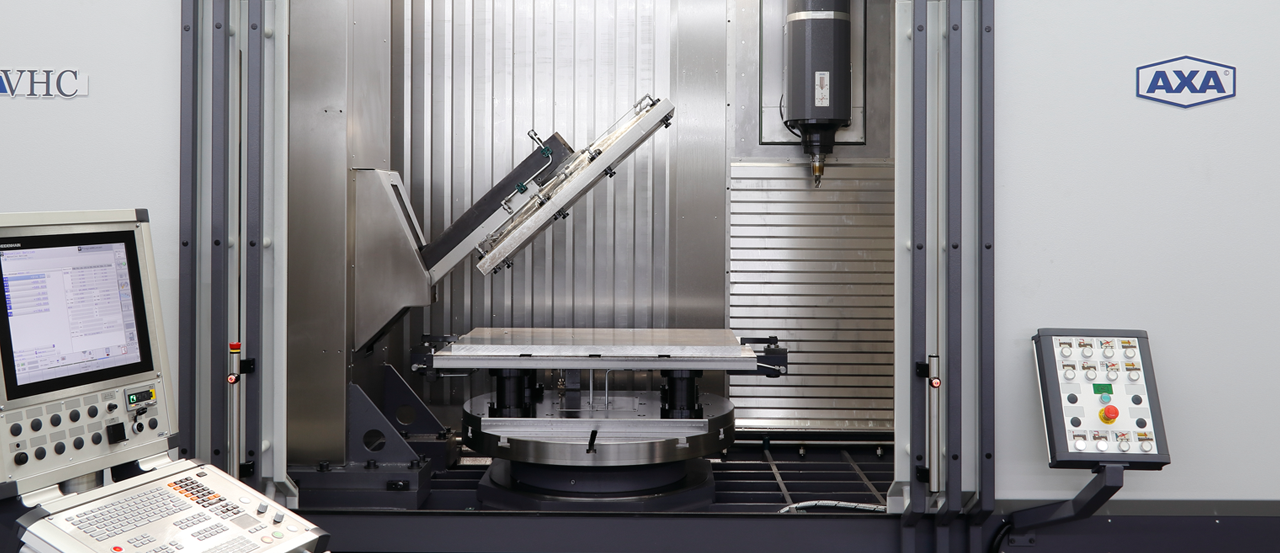

Type of machine: Travelling column machining centres VSC and VHC

Task:

|

Workpiece 1: Frame for the floor plate |

Type of machine:Travelling column machining centre VSC 3 - 1760 |

Material:Extruded aluminium profiles, welded together to a frame |

Solution:Hydraulic clamping device for the workpiece with three clamping circuits mounted on a bridge between the rotary table and the counter bearing |

Special characteristics:

|

Traverse ranges:X-traverse range: 1760 mm |

Spindel:Main spindle drive (with 40% DC): 40 kW |

Tool changing system:Pick-up station with 8 tool pockets for HSK A63 |

NC-rotary table:AXA RTA 3-630 (face plate 630 mm), Swivel range +200° up to -10° |

Counter bearing:Rotary table AXA RT 2 |

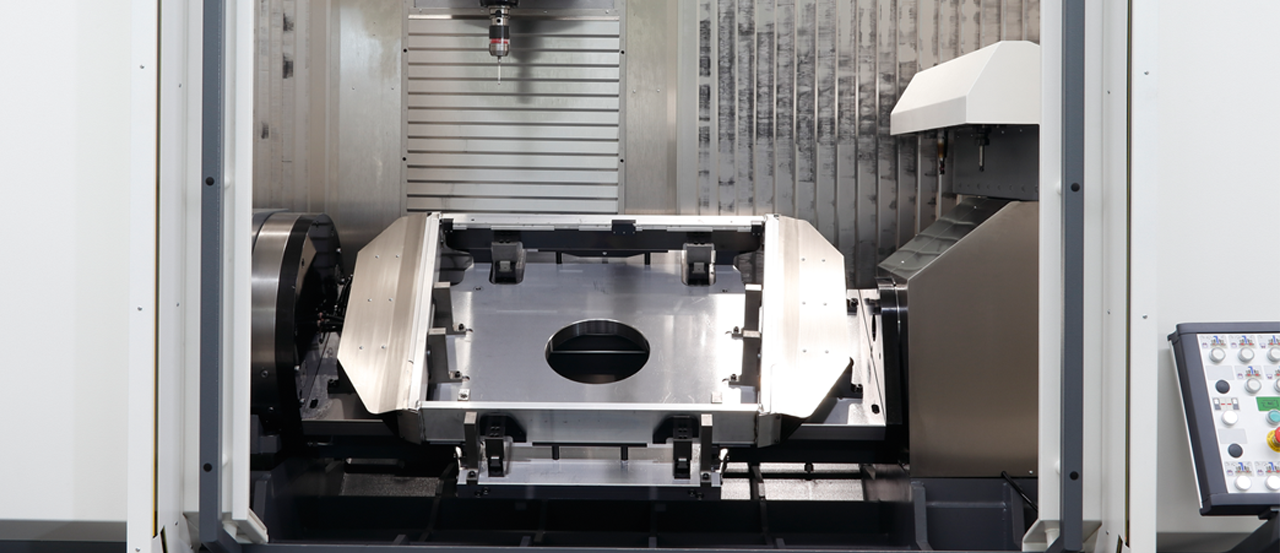

Workpiece 2: Floor plate for the battery housing

Type of machine:Travelling column machining centre VHC 3 - 1760 XTS |

Material:Extruded aluminium profiles, joined by friction stir welding |

Solution:Hydraulic clamping device for the workpiece with four clamping circuits, consisting of a clamping plate with eight hydraulic stamps, which clamps the workpiece onto the support plate of the rotary table by a hydraulically driven extension arm. The workpiece is positioned against the stop bolts and is held by the swivel clamps during the lifting and lowering movement of the extension arm. As soon as the workpiece is clamped by the eight hydraulic stamps, the stop bolts and the additional swivel clamps move back and enable the machining of the requested area. The clamping plate is mounted rotatable in the extension arm which enables the workpiece to be positioned by the rotary table during machining. 1. circuit: Stop bolts (alignment of the workpieces in X/Y-direction) |

Special characteristics:The whole machining of the four sides by vertical and horizontal spindle position takes place in one clamping due to the special clamping device. |

Traverse ranges:X-traverse range: 1760 mm |

Spindle:Main spindle drive (with 40% DC): 40 kW |

Tilting spindle head:hydraulically clamped during machining |

Tool changing system:XTS tool magazine with 16 tool pockets for HSK A63 |

NC-rotary table:AXA RTA 4TF-1000 (face plate 1000 mm) |