Task:Incremental sheet metal forming for a body component |

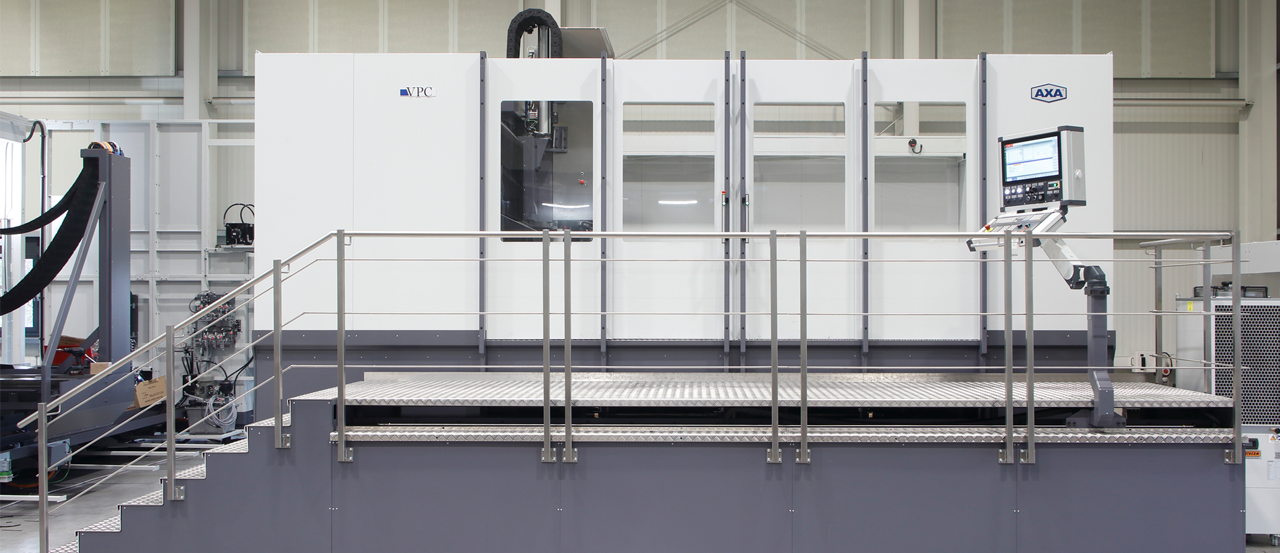

Solution:- Use of portal machining centre VPC 2800 U

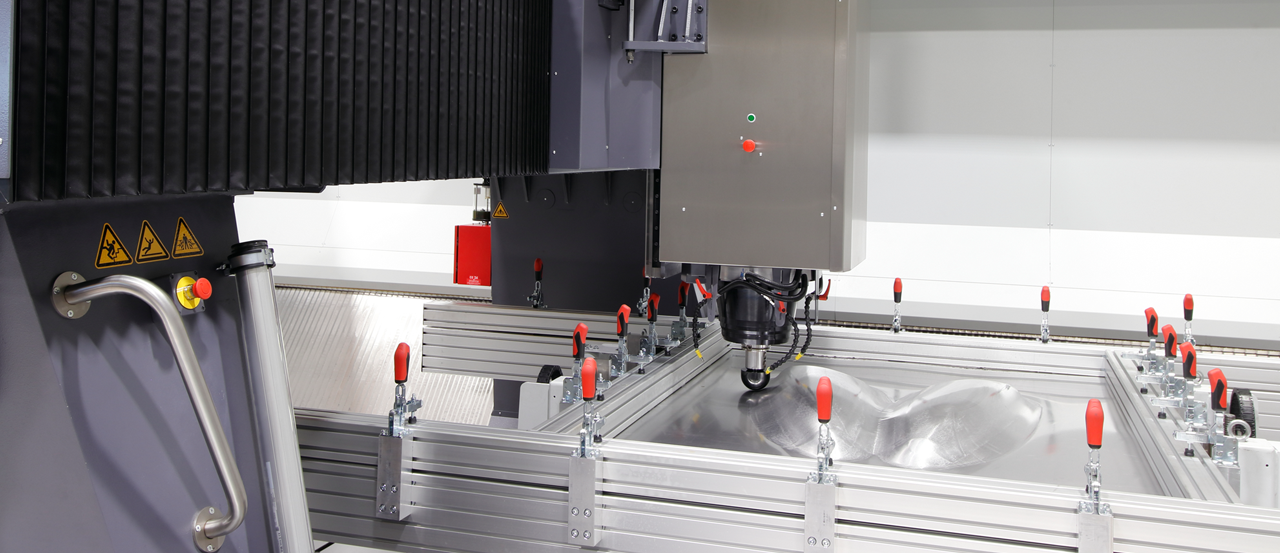

- A wood-based material is used as the counter-tool for the body component. The sheet metal to be processed is clamped in a frame over this tool. The final shape is generated through multiple successive movements of a CNC-controlled forming tool.

|

Special features:- Minimal tooling costs and therefore cost efficiency from a batch size of one

- Production of sheet metal components with complex geometries in the shortest possible time

|

Working area:X-traverse range: 3900 mm

Y-traverse range: 2940 mm

Z-traverse range: 900 mm |

Spindle:Main drive (S1): 32 kW

Spindle torque (S1): 407 Nm

Speed range: up to 2300 rpm |

Tool changing system:Pick up tool magazine, HSK A100 |

Clamping device:Height-adjustable sheet metal clamping frame |