VPC 2800 U - Gantry machining centre

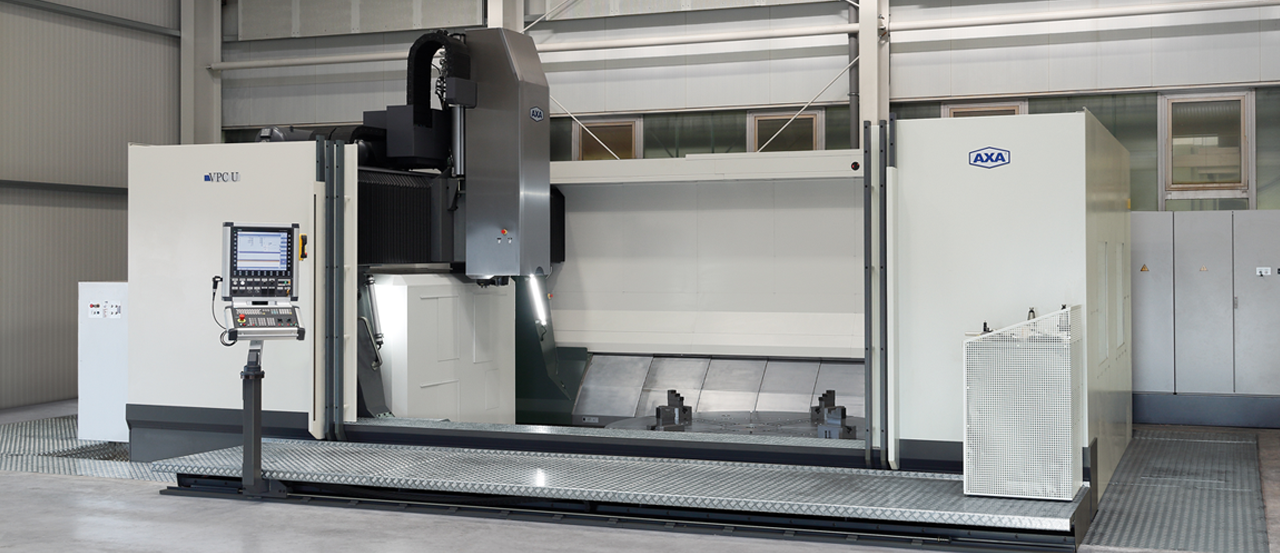

The VPC 2800 U unites the advantages of the compact built VPC range with the working area proportions of the spacious portal machining centres PFZ/UPFZ from AXA. Its travel of up to 5000 x 2940 x 1300 mm makes this multitalent stand out above the competition for large gantry machines. The compact construction integrates all the essential components in very confined space.

5-sides and 5-axes machining of large cubic workpieces is a simple task for the VPC 2800 U: The combination of a stepless interpolating 1-axis tilting head with a rotary table integrated into the frame makes this task simplicity itself.

Main design

Main design

- Extremely rigid, static and dynamically well balanced ground frame construction

- Spacious and easily accessible machine tables

- Direct measuring systems for X/Y/Z axes

- Cover according to current machinery directives

- Ideal for crane loading by the open covering over the work area

- Machine transport in one single piece

- Optimal accessibility for all maintenance and service requirements

In addition, the VPC 2800 U can be flexibly extended, for example:

- Through spindle coolant with filter system

- Chip conveyor in slat-band belt, scraper belt or magnetic belt versions

- Controllers either from Heidenhain or Siemens

- Automatic doors

- Clamping systems – hydraulic, pneumatic, magnetic or manual

- Touch probes and tool touch probe systems

- Active power monitoring, collision monitoring and complete process monitoring

- Tool identification systems

- Laser breakage control with tool measurement

- Remote maintenance

Guideways and drives

Guideways and drives

- Large-scale dimensioned roller guideways for high dynamics and stiffness

- Optimal guiding by extremely large guidance ratio

- Real gantry drive in the X-axis with corresponding individual drive, guideway and direct measuring system for both portal columns

- Drives and guideways are protected

- Ball screws in all linear axes

Tool changing system

Tool changing system

- Simple and very robust stationary placed tool changer

- Magazine protected in rear part of machine

- Stationary tool changer layout allows for long tool chains without any negative effect on machine dynamics and precision

- Fixed location coded tool management for better operator monitoring

- Simultaneous tool pre-selection by double gripping system

- Support of various tool holding systems such as SK, BT, HSK, CAPTO

- Magazine placement possible during machining

Tilting spindle

Tilting spindle

↵

- 1-axis tilting spindle swivelling around the Y-axis (B-axis)

- stepless interpolating

- Tilting range 0° to -90°

Rotary table

Rotary table

- Continuous turning NC-rotary table around the Z-axis

- Integrated in machine bed

- Hydraulic clamping

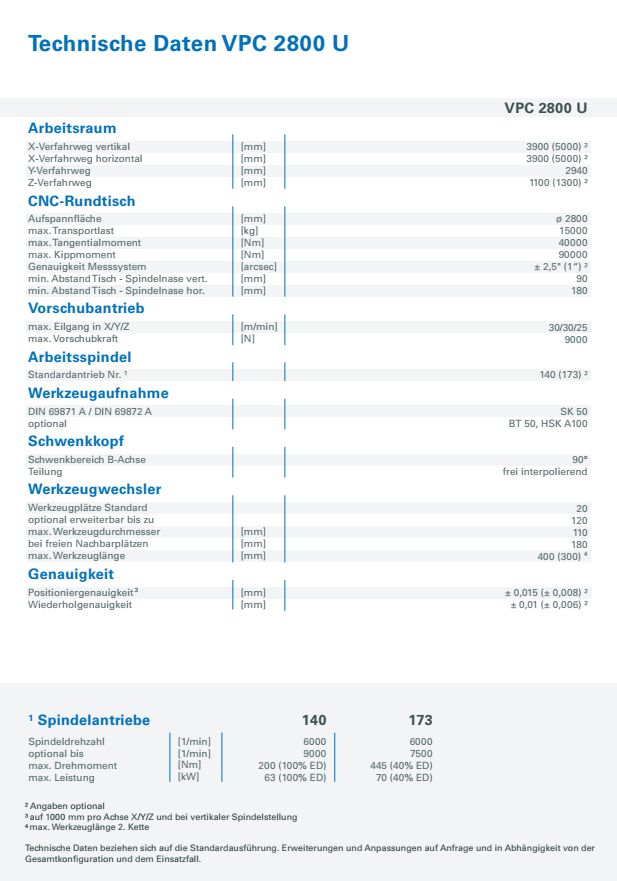

Technical data

Technical data

Click to open or download the technical data as pdf file.

Product brochure

Product brochure

For more information about our VPC 2800 U please have a look at the brochure. Click here to open or download the pdf file.

Examples of use