Gantry machining centre VPC

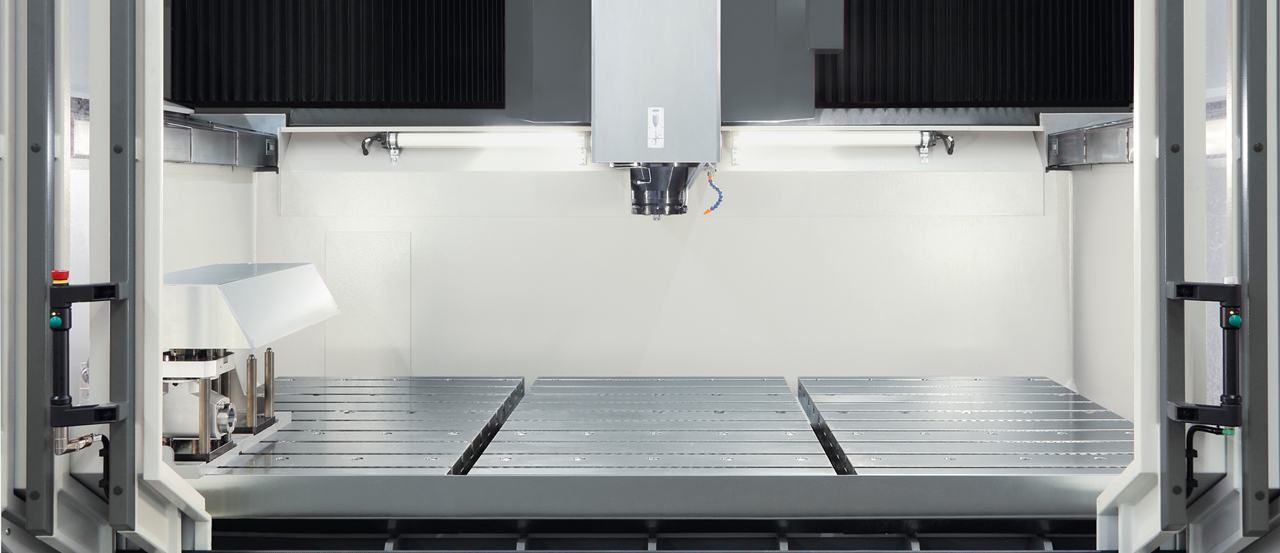

The VPC with its vertical spindle is particularly designed for machining large plate-shaped workpieces. The implementation of angular heads also simply enables lateral machining. The clever layout provides for excellent workspace use. The portal drives the spindle above a real gantry drive in the Y-axis. The machine footprint is thus hardly larger than the optimally arranged working area.

Main design

Main design

- Extremely rigid, static and dynamically well balanced ground frame construction

- Spacious and easily accessible machine tables

- Direct measuring systems for X/Y/Z axes

- Cover according to current machinery directives

- Ideal for crane loading by the open covering over the work area

- Machine transport in one single piece

- Optimal accessibility for all maintenance and service requirements

In addition, the VPC can be flexibly extended, for example:

- Through spindle coolant with filter system

- Chip conveyor in slat-band belt, scraper belt or magnetic belt versions

- Controllers either from Heidenhain or Siemens

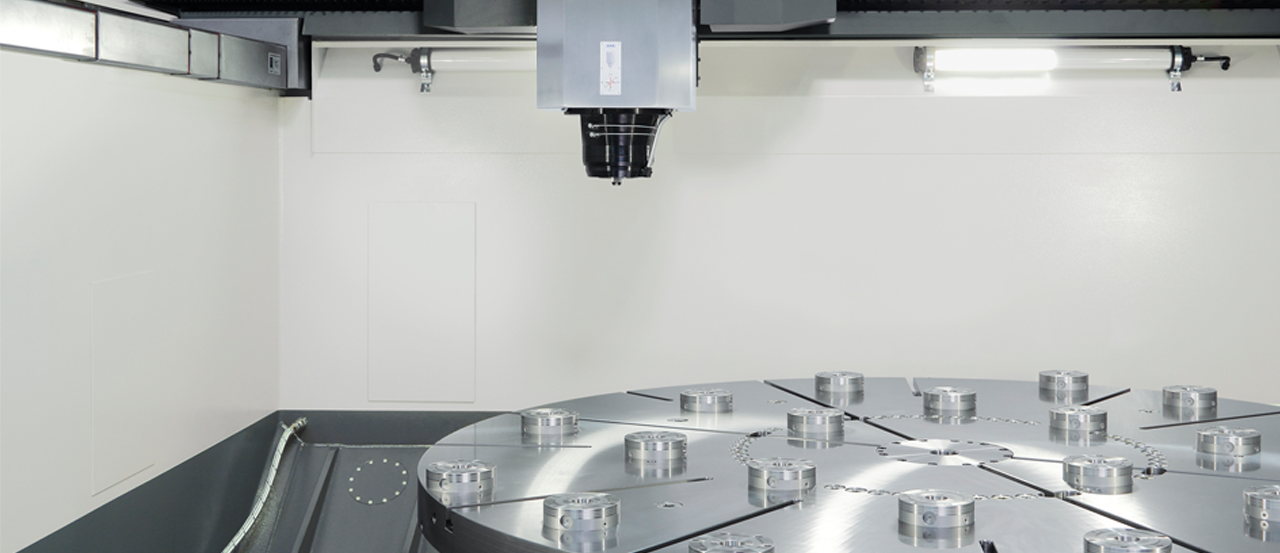

- Rotary tables horizontally or vertically integrated, in 1 or 2 axes, combined with tailstocks, counterbearings or a further rotary table in gantry mode for clamping bridges

- Automatic doors

- Clamping systems – hydraulic, pneumatic, magnetic or manual

- Touch probes and tool touch probe systems

- Active power monitoring, collision monitoring and complete process monitoring

- Tool identification systems

- Laser breakage control with tool measurement

- Remote maintenance

Guideways and drives

Guideways and drives

- Combination of sliding and roller guideways for high dynamics, stiffness and absorption

- Guiding built upon manually scraped or grinded surface

- Optimal guiding by extremely large guidance ratio

- Real gantry drive in the Y-axis with corresponding individual drive, guideway and direct measuring system for both portal sides

- Drives and guideways are protected

- Ball screws in all linear axes

Tool changing system

Tool changing system

- Simple and very robust stationary placed tool changer

- Magazine protected in rear part of machine

- Stationary tool changer layout allows for long tool chains without any negative effect on machine dynamics and precision

- Fixed location coded tool management for better operator monitoring

- Simultaneous tool pre-selection by double gripping system

- Support of various tool holding systems such as SK, BT, HSK, CAPTO

- Magazine placement possible during machining

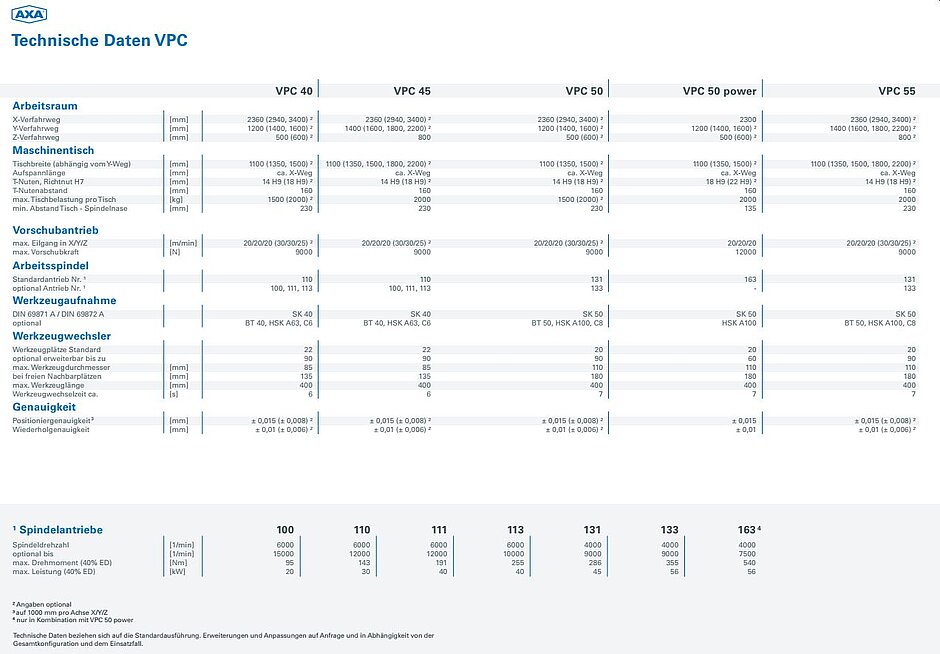

Technical data

Product brochure

Product brochure

For more information about our VPC please have a look at the brochure. Click here to open or download the brochure as pdf file.

Examples of use

Examples of use

Application videos

Application videos

Choose one of the following videos about our VPC: