Tool changing systems

The correct tool changing system is inseparably linked to the machine tool. Given the large number of different machining scenarios, it is always necessary to select the optimum tool changing system. We design and manufacture this important core component ourselves and can therefore always offer our customers the best concept for them.

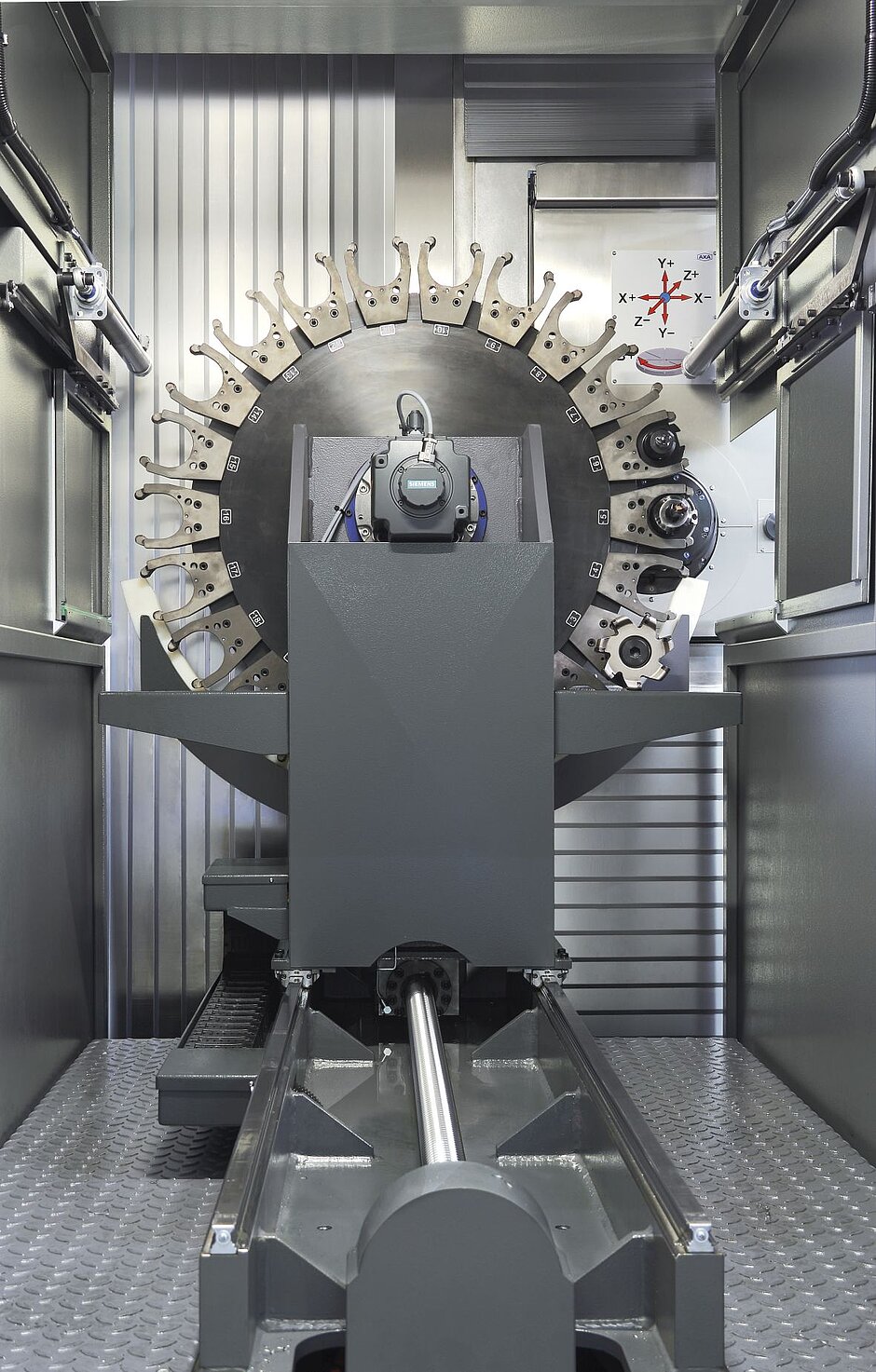

Disc-type magazines

Disc-type magazines

- As vertical and horizontal solution

- Fixed location coded tool management enables better monitoring for the operator

- Support of various tool holding systems such as SK, BT, HSK

- Tool magazine is protected outside of working area

- Set-up of the magazine with tools during machining possible

- Tool change takes place behind working area cladding

- Up to 30 tool pockets

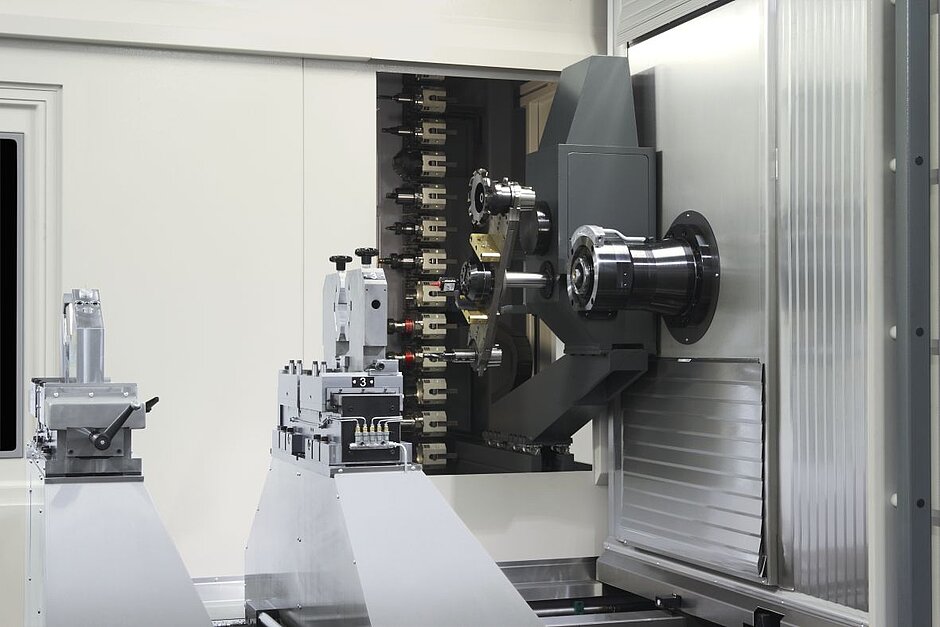

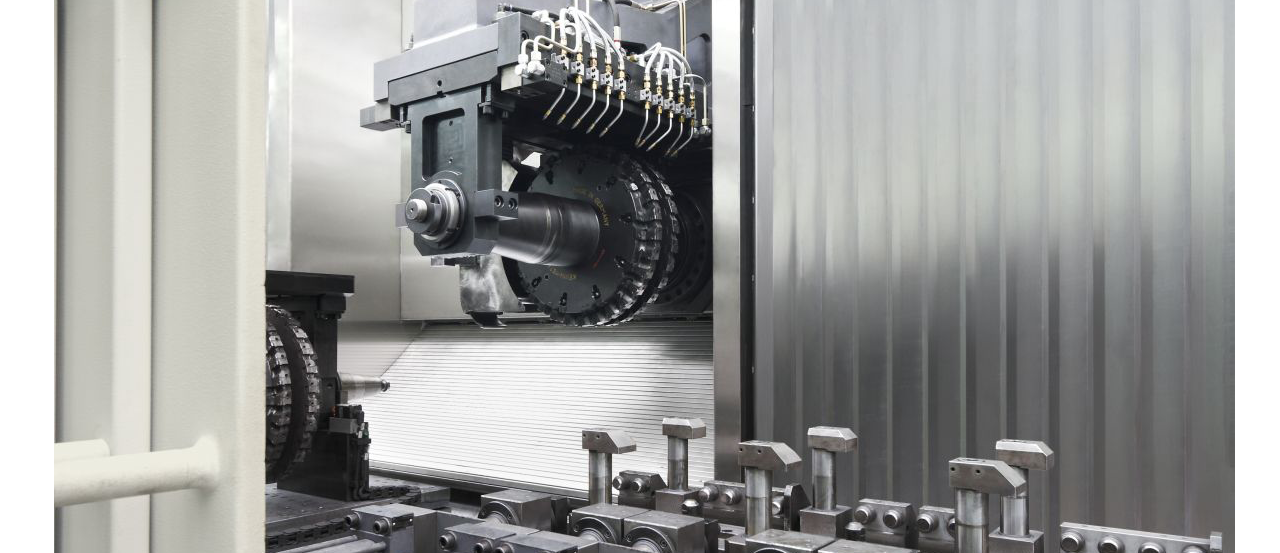

Chain magazines

Chain magazines

- As vertical and horizontal solution

- Simple and very robust stationary placed tool changer

- Magazine protected in rear part of machine

- Stationary tool magazine layout allows for long tool chains without any negative effect on machine dynamics and precision

- Fixed location coded tool management for better operator monitoring

- Tool pre-selection by double gripping system during machining

- Support of various tool holding systems such as SK, BT, HSK, CAPTO

- Set-up of the magazine with tools during machining possible

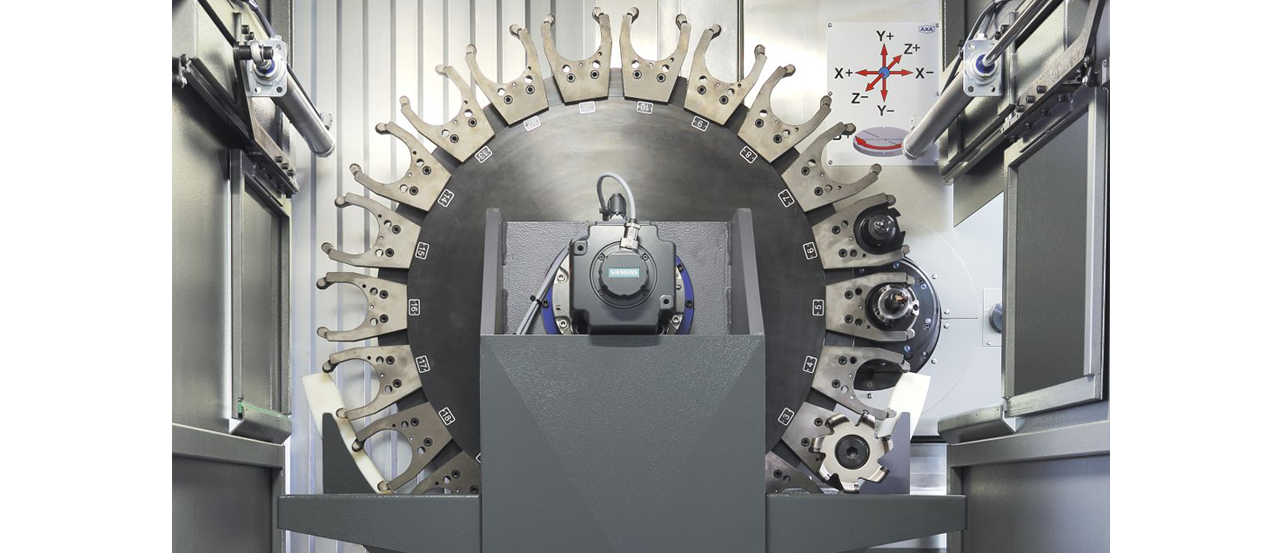

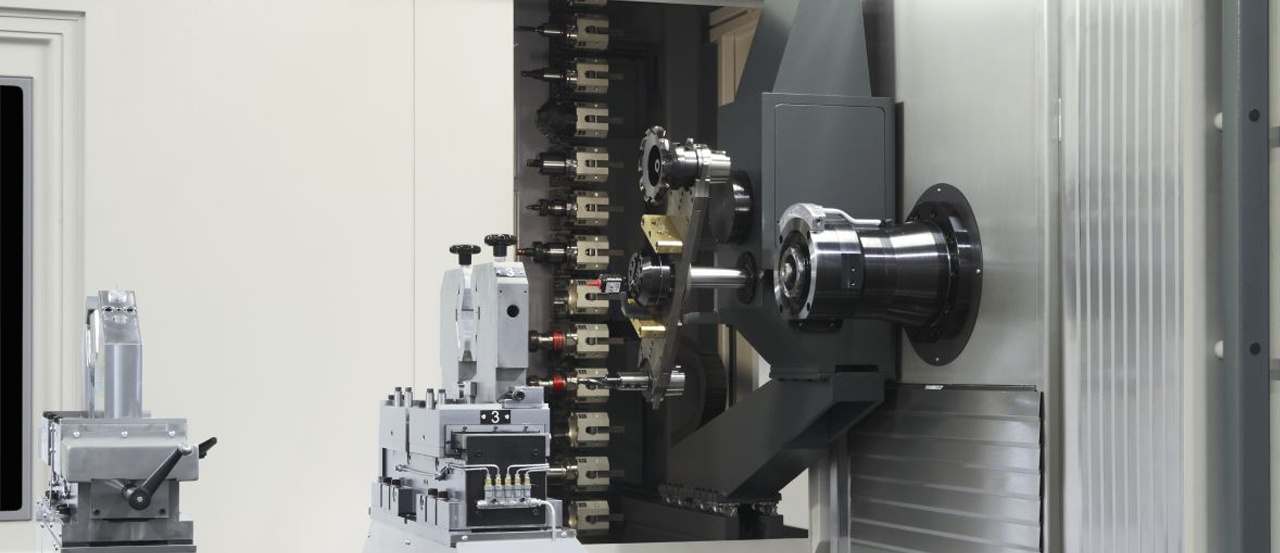

XTS tool magazine

XTS tool magazine

- Tool magazine is protected outside of working area

- Set-up of the magazine with tools during machining possible

- Tool change takes place behind working area cladding, in this case no risk of collision with the workpiece during the tool change process

- Tool changer with double gripping system from XTS magazine has its own drive and moves at up to 120 m/min to the spindle position for the tool change

- Any number of tool pockets are possible by several compact XTS towers

- Fixed location coded tool management enables better monitoring for the operator

- Tool pre-selection by double gripping system during machining

- Support of various tool holding systems such as SK, BT, HSK, CAPTO

- Tool pockets within a tower or magazine can also be expanded at any point in time in the future

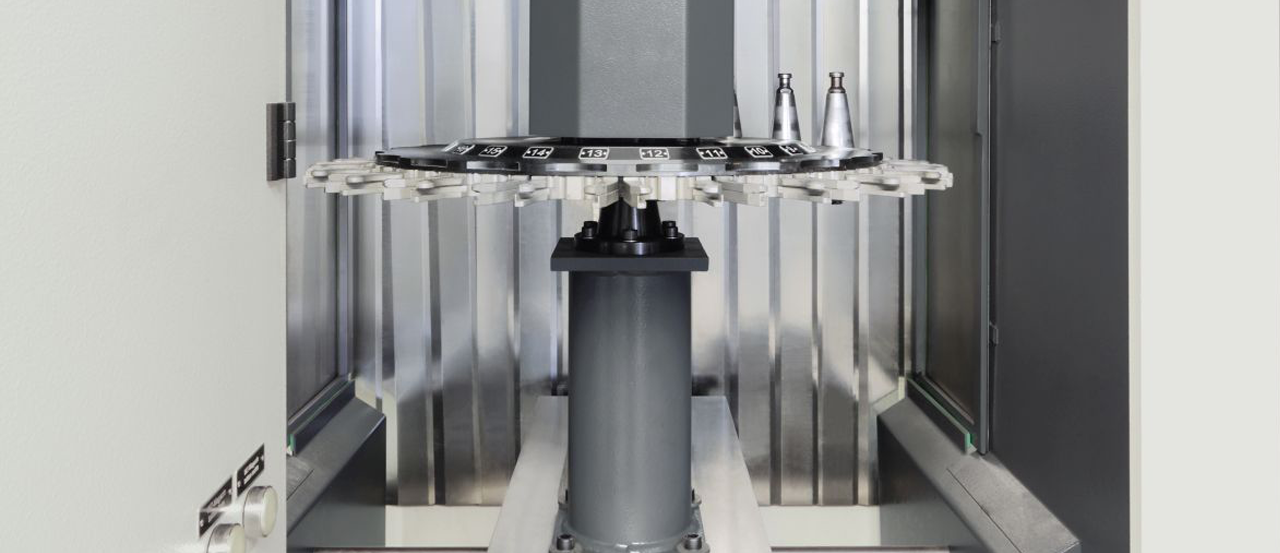

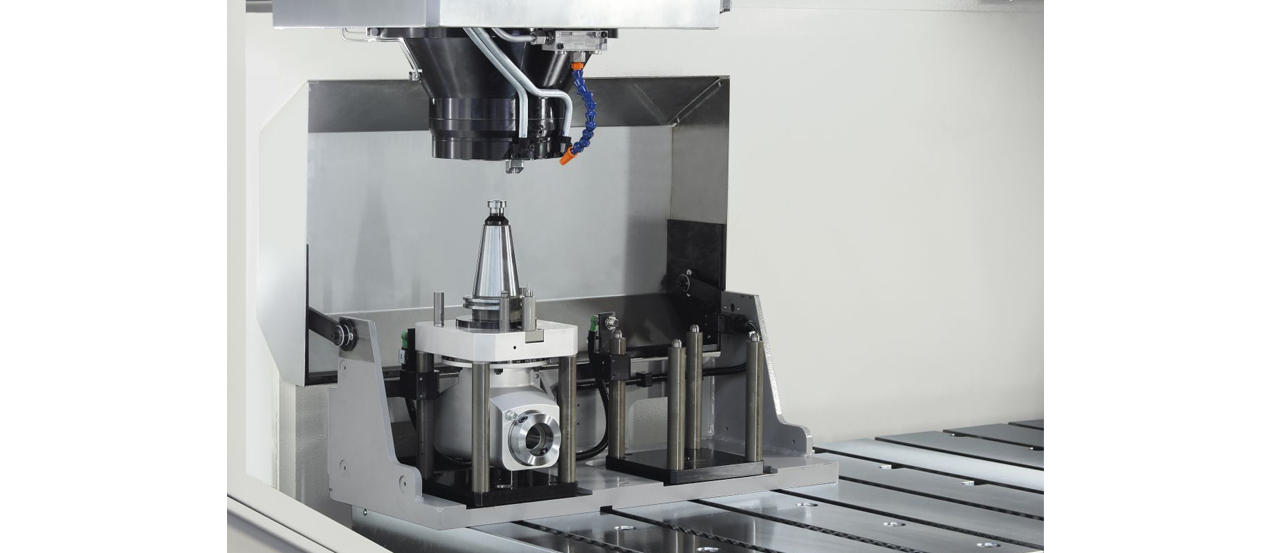

Pick up stations

Pick up stations

- As vertical and horizontal solution

- Tool range can be flxibly and subsequently extended

- Optimal solution for special tools, angle heads or multi-spindle heads

- Pick up stations can be removed

- Fixed mounting in the working area of the machine

- Spindle changes the tool directly from the pick up magazine

Product brochure

Product brochure

For more information about our original components please have a look at the broschure. Click here to open or download the brochure as pdf file.