Travelling column machining centre VSC

Clear in structure - flexible in their assembly

The VSC is versatile - from the small machine variant to the sophisticated machines for large and complex work pieces. The combination of fixed machine tables with linear motion axes on the tool side opens a whole world of possibilities.

The VSC is also capable of operation in pendulum processing machining mode, which minimises set-up times so as to be quickly ready for operation.

Traverse ranges up to X = 10000 mm, Y = 1250 mm, Z = 1250 mm

Main design

Main design

- Cross slides, travelling columns and spindle head stock are made from high-quality cast iron

- Extremely rigid, static and dynamically well balanced ground frame construction

- Direct measuring systems for X/Y/Z axes

- Casing according to current machinery directives, totally closed working area with no interfering contours - also in pendulum operation mode

- Total access to working area when doors are fully open

- Excellent accessibility for maintenance and service tasks

- Machine transport in one piece

In addition, the VSC can be flexibly extended, for example:

- Through spindle coolant with filter system

- Chip conveyor in slat-band belt, scraper belt or magnetic belt versions

- Controllers either from Heidenhain or Siemens

- Rotary tables horizontally or vertically integrated, in 1 or 2 axes, combined with tailstocks, counterbearings or a further rotary table in gantry mode for clamping bridges.

- Automatic doors

- Clamping systems – hydraulic, pneumatic, magnetic or manual

- Touch probes and tool touch probe systems

- Active power monitoring, collision monitoring and complete process monitoring

- Tool identification systems

- Laser breakage control with tool measurement

- Remote maintenance

Guideways and drives

Guideways and drives

- Hardened precision steel slideways mounted on manually scraped or grinded surfaces

- Optimal guiding by extremely large guidance ratio and Turcite coatings

- High rigidity, outstanding long-term precision performance and excellent vibration absorbing capabilities of the guideways

- Excellent resetting and adjustability of the guideways

- Drives and guideways are protected set outside of working area

- Ball screws in all linear axes with patented support units for ball screws in the X-axis for large travel lengths

Tool changing system

Tool changing system

- Fixed location coded tool management enables better monitoring for the operator

- Tool pre-selection by double gripper arm during machining

- Support of various tool holding systems such as SK, BT, HSK, CAPTO

- Tool magazine is protected outside of working area

- Placement of the XTS magazine during machining possible

- Tool change takes place behind working area cladding: no disturbing contours in the working area during tool change by the gripper or parts

- Transport unit from XTS magazine has its own drive and moves at up to 120 m/min to the spindle position for the tool change

- Any number of tool pockets are provided by several compact XTS towers

- Tool pockets within a tower can also be expanded at any point in time in the future

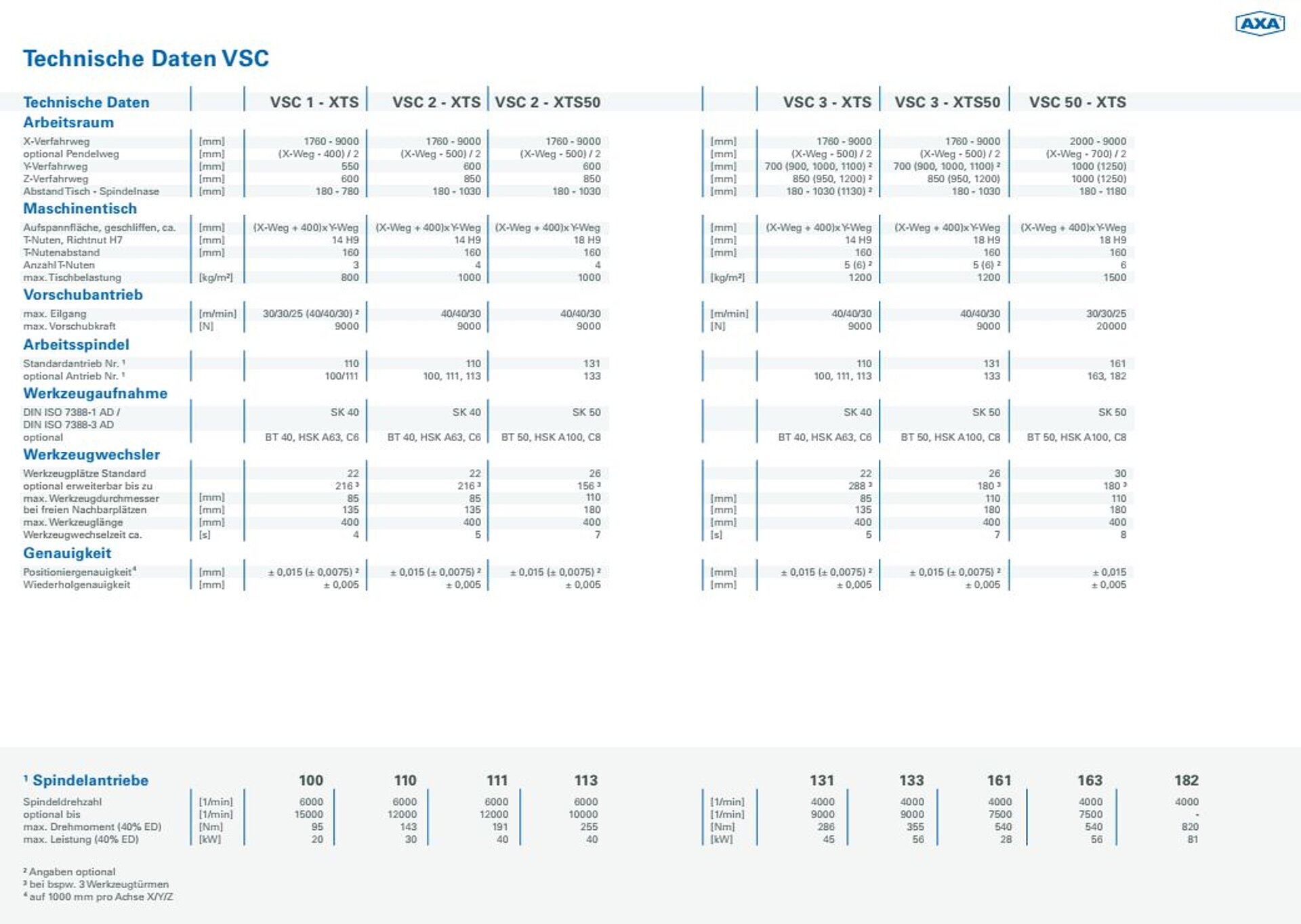

Technical data

Product brochure

Product brochure

For more information about our VSC please have a look at the product brochure. Click here to open or download the pdf file.