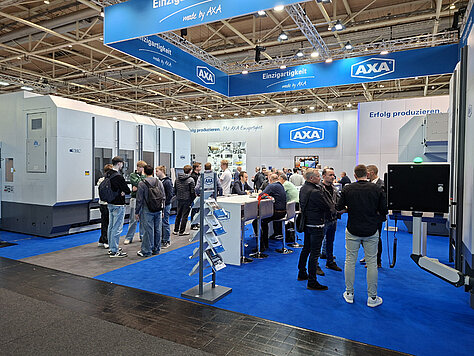

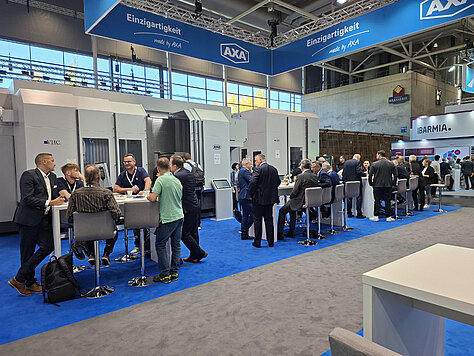

AXA Maschinenbau at EMO Hannover

As the world's leading trade fair for the manufacturing industry, EMO offers a unique platform for the exchange of knowledge, innovations and business opportunities – the perfect opportunity to find out about international markets and new products and to exchange ideas.

Thank you for sharing your thoughts with us!

Our trade fair exhibits in detail:

Travelling column machining centre VSR 2

We are expanding our machine series – with the VSR 2 travelling column machining centre with swivelling rotary table for 5-axis or 5-sided machining of smaller components.

What makes the VSR 2 special:

- Swivelling rotary table that swivels around the Y-axis: Unlike the usual swivelling around the X-axis, this solution allows a clear view of any interfering contours.

- Extremely compact: It requires an unusually small footprint of around 12 square metres. The rear is completely closed so that the machine can be placed directly against a wall.

- Space-saving tool magazine: a magazine tower with two chains for 60 and 24 tools

- Robot interface: The travelling column design allows for a side lifting gate for automated loading. This connection does not obstruct access to the work area and allows for unrestricted operation.

- Heidenhain TNC 7 control

Traverse ranges:

X = 1100 mm

Y = 600 mm

Z = 700 mm

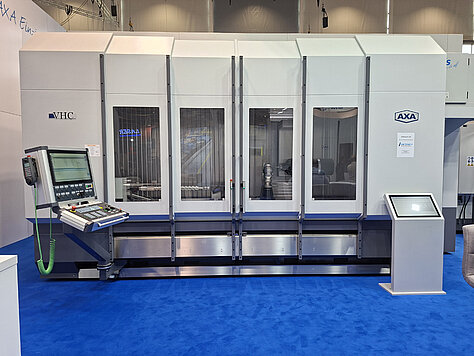

VHC 3-2600 XTS EDITION

The VHC 3 EDITION based on our successful VHC travelling column machining centre

What makes the VHC 3-2600 XTS EDITION special:

- Swivel spindle as the core element

- 5-axis- and 5-sided machining of workpieces in a single clamping

- Two additional rotary tables – what makes it a 6-axes-machining centre:

AXA rotary table RTA 4TF (Ø 1000 mm) integrated into the machine table

AXA rotary table RTA 2-300 (Ø 300 mm) fixed vertically on the machine table

- Tailstock as counterbearing

- Siemens Sinumerik One control

Traverse ranges:

X = 2600 mm / pendulum mode 2 x 1050 mm

Y = 900 mm

Z = 950 mm

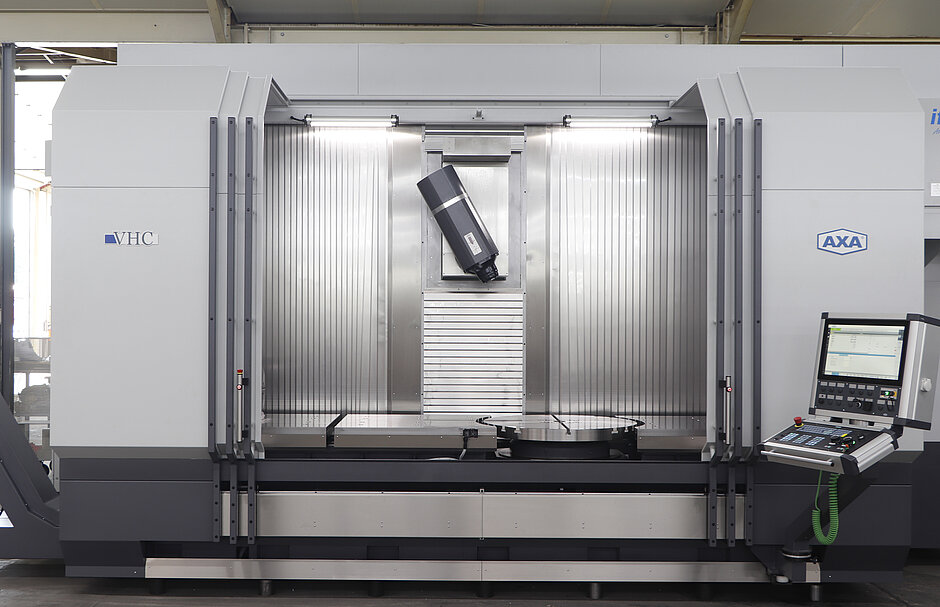

VHC 3-2600 XTS 50-FD

The 5-axes-travelling column machining centre VHC with milling and turning function

What makes the VHC 3-2600 XTS 50-FD special:

- Two different tool changing systems:

Milling tools: the tool magazine comprises three individual chains, each with 36 HSK A100 tool places

Turning tools: a disc magazine with 16 CAPTO C6 tool places that moves with the travelling column

- A separate disc magazine for CAPTO C6 tools which moves with the travelling column

The XTS tool magazine is reserved exclusively for HSK tools and can be equipped with up to three chains of 36 tools each

- The turning tool holder for CAPTO C6 tools beside the HKS A100 main spindle drive

This separate clamping unit for turning tools ensures the clear orientation of the turning tools and at the same time avoids additional stress on the main spindle bearing.

- Equipped with a swivel spindle and the RTA 5 TD rotary table with 850 mm face plate (turning operation max. 500 rpm) integrated into the machine table

- With Heidenhain TNC 7 control

Traverse ranges:

X = 2600 mm

Y = 900 mm

Z = 950 mm